The Science of SBR Latex and Its Role in Waterproofing

The article covered here delves into the science behind Styrene Butadiene Rubber (SBR) latex and its significant role in waterproofing applications. SBR latex, a synthetic polymer derived from styrene and butadiene, possesses unique properties that make it an effective material for waterproofing various surfaces. This article explores the composition, manufacturing process, and key characteristics of SBR latex, along with its mechanisms for enhancing waterproofing performance. Furthermore, it highlights the applications and benefits of SBR latex-based waterproofing systems in diverse industries.

Introduction to SBR Latex: Styrene Butadiene Rubber

Waterproofing is a crucial requirement in numerous industries, such as construction, textiles, automotive, and marine. SBR latex has emerged as a versatile material for waterproofing due to its exceptional properties, including excellent adhesion, flexibility, durability, and water resistance. Understanding the science behind SBR latex and its mechanisms of action can shed light on its efficacy as a waterproofing agent.

Composition and Manufacturing Process of SBR Latex

In this segment of our article, we will dive into details of how SBR latex is produced and its composition, which helps in justifying its waterproofing properties.

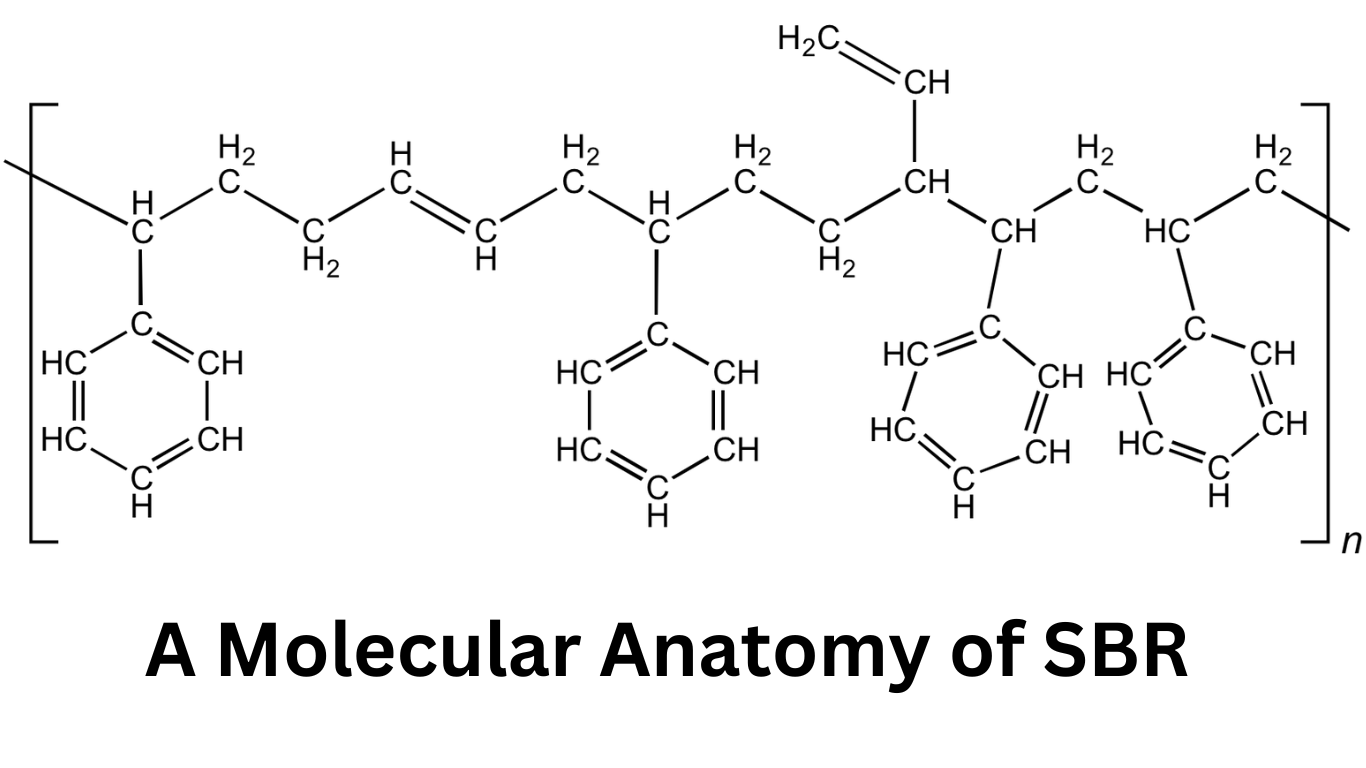

2.1 Composition of SBR Latex: Styrene Butadiene Rubber

SBR latex is a synthetic copolymer consisting of styrene and butadiene units. The ratio of styrene to butadiene can vary depending on the desired properties of the final product. SBR latex typically contains around 70-75% water, with the remaining percentage being composed of polymer solids and various additives.

2.2 Manufacturing Process of SBR Latex: Styrene Butadiene Rubber

SBR latex is produced through an emulsion polymerization process. In this process, styrene and butadiene monomers are emulsified in water with the aid of surfactants and emulsifying agents. The emulsion is then subjected to polymerization, usually through the addition of a free radical initiator. This leads to the formation of polymer particles suspended in water, resulting in SBR latex.

Key Characteristics of SBR Latex for Waterproofing

Now that we know about the composition of SBR Latex and how it is produced let’s delve into the key characteristic of SBR Latex, which plays a huge role in ensuring sound waterproofing solution.

3.1 Adhesion property of SBR Latex: Styrene Butadiene Rubber

SBR latex exhibits excellent adhesion to various substrates, including concrete, metals, textiles, and plastics. The polymer chains of SBR latex form strong intermolecular bonds with the surface, promoting adhesion and preventing water penetration.

3.2 Flexibility and Durability of SBR Latex: Styrene Butadiene Rubber

SBR latex imparts flexibility and durability to waterproofing coatings or membranes. The rubber-like nature of the polymer allows it to withstand movements, expansions, and contractions of the substrate without cracking or losing its waterproofing properties.

3.3 Water Resistance property of SBR Latex: Styrene Butadiene Rubber

SBR latex itself is inherently water-resistant, making it an ideal material for waterproofing applications. The polymer chains repel water molecules, preventing their ingress into the substrate.

Mechanisms of SBR Latex in Waterproofing

Now that we have an overall understanding of the key characteristics of SBR Latex, let’s walk through how it functions.

4.1 Film Formation Mechanism of SBR Latex: Styrene Butadiene Rubber

When SBR latex is applied as a coating or membrane, it forms a continuous film over the surface. This film acts as a physical barrier, preventing the passage of water molecules through the substrate.

4.2 Hydrophobicity Mechanism of SBR Latex: Styrene Butadiene Rubber

SBR latex exhibits hydrophobic properties due to the presence of non-polar hydrocarbon chains in its structure. These hydrophobic segments repel water, further enhancing the waterproofing capability of SBR latex-based systems.

4.3 Enhanced Adhesion function of SBR Latex: Styrene Butadiene Rubber

The polymer chains of SBR latex penetrate the substrate surface and establish strong adhesion, improving the waterproofing performance. This adhesion prevents the displacement or detachment of the waterproofing layer, even under challenging conditions.

Applications and Benefits of SBR Latex-Based Waterproofing Systems

Now that we have a clear understanding of SBR Latex’s mechanism, let’s walk you through the different applications and benefits of the compound in a waterproofing system.

5.1 Application and Benefit of SBR Latex in the Construction Industry

SBR latex-based waterproofing systems are extensively used in construction for sealing and protecting concrete structures, roofs, basements, and tunnels. They provide long-lasting protection against water ingress, thus preventing structural damage and ensuring the longevity of buildings.

5.2 Application and Benefit of SBR Latex in the Textile Industry

SBR latex is applied to fabrics and textiles to impart water repellency, making them suitable for outdoor clothing, tents, and other applications that require waterproof or water-resistant properties.

5.3 Application and Benefit of SBR Latex in the Automotive and Marine Industries

SBR latex-based coatings are used in automotive and marine applications to protect against moisture, corrosion, and water damage. They provide a protective barrier on surfaces exposed to harsh environments, such as vehicle underbodies and boat hulls.

Denouement

SBR latex is a scientifically advanced material with exceptional properties that make it highly effective in waterproofing applications. Its adhesion, flexibility, durability, and water resistance contribute to its success as a waterproofing agent. Understanding the science behind SBR latex allows for its optimal utilization in various industries, ensuring reliable and long-lasting waterproofing solutions.