The Science behind Admixtures: Enhancing Concrete Durability and Strength

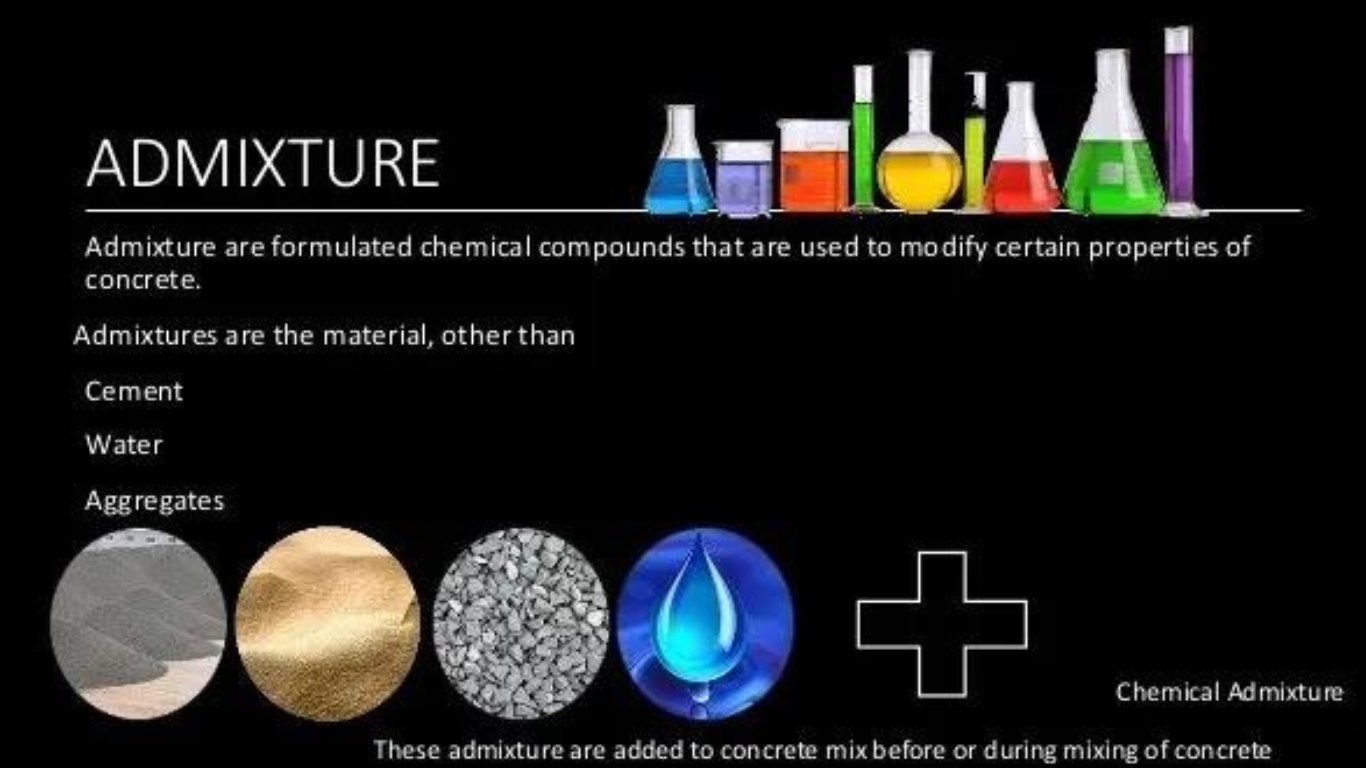

Concrete is the most widely used construction material in the world. It is strong, durable, and can be molded into almost any shape. However, even the best concrete mixes can have their limitations. To overcome this limitation scientists across the world came up with the invention of Admixtures. A chemical compound, added to concrete to enhance its properties and overcome the limitations.

Introduction to Admixtures in Concrete

Admixtures are used in concrete to improve its workability, durability, and strength. They are added to the concrete mix during the mixing process and become an integral part of the final product. Admixtures can be used to modify the properties of fresh concrete, set and hardening times, and the strength and durability of the hardened concrete.

What are Admixtures & Why are they Used in Concrete?

Admixtures are chemical compounds added to concrete to modify its properties. They are used to improve the workability of fresh concrete, reduce the water content needed for given workability, control setting time, increase strength, and improve durability.

Admixtures are used in concrete for a variety of reasons. For example, they can help to reduce the amount of water needed in the mix, which in turn reduces the concrete’s permeability and improves its strength. They can also be used to improve the workability of the mix, making it easier to place and finish.

Types of Admixtures Used in Concrete

There are many types of admixtures used in concrete, each with its own specific purpose. Some of the most common types of admixtures include water-reducing admixtures, air-entraining admixtures, and superplasticizers.

Water Reducing Admixtures and Their Benefits

Water-reducing admixtures are used to reduce the amount of water needed to achieve a given workability. These admixtures work by dispersing the cement particles more efficiently, which reduces the amount of water needed to achieve the same level of workability.

The benefits of water-reducing admixtures include increased strength, improved durability, and reduced permeability. By reducing the amount of water in the mix, water-reducing admixtures also reduce the amount of shrinkage that occurs during the curing process, which can help to prevent cracking.

Air-Entraining Admixtures and Their Benefits

Air-entraining admixtures are used to introduce microscopic air bubbles into the concrete mix. These bubbles help to improve the workability of the mix and increase its resistance to freeze-thaw cycles.

The benefits of air-entraining admixtures include increased workability, increased resistance to freeze-thaw cycles, and improved durability. By introducing air bubbles into the mix, these admixtures also help to reduce the amount of bleed water that occurs during the curing process, which can help to prevent surface defects.

Superplasticizers and Their Benefits

Superplasticizers are used to improve the workability of the concrete mix without increasing the water content. They work by dispersing the cement particles more efficiently, which allows the mix to be more easily molded and shaped.

The benefits of superplasticizers include improved workability, increased strength, and reduced permeability. Further, superplasticizers reduce the amount of water needed in the mixture, which in turn also helps to reduce the amount of shrinkage that occurs during the curing process, which can help to prevent cracking.

Other Types of Admixtures Used in Concrete

In addition to water-reducing admixtures, air-entraining admixtures, and superplasticizers, there are many other types of admixtures used in concrete. Some of these include retarding admixtures, accelerating admixtures, and corrosion inhibitors.

Retarding admixtures are used to delay the setting time of the concrete, which can be useful in hot weather or when the concrete needs to be transported over long distances.

Accelerating admixtures, on the other hand, are used to speed up the setting time of the concrete, which can be useful in cold weather or when the concrete needs to be used quickly.

Corrosion inhibitors are used to protect the concrete from the effects of corrosion. They work by preventing the corrosion of the reinforcing steel in the concrete, which can help to increase its durability and prevent structural damage.

How Admixtures Enhance Concrete Durability and Strength

Admixtures can enhance the durability and strength of concrete in a number of ways. For example:

- Water-reducing admixtures reduce the amount of water needed in the mix, which in turn reduces the concrete’s permeability and improves its strength.

- Air-entraining admixtures introduce microscopic air bubbles into the mix, which can help to improve the concrete’s resistance to freeze-thaw cycles.

- Superplasticizers improve the workability of the mix without increasing the water content, which can help to reduce the amount of shrinkage that occurs during the curing process.

By enhancing the durability and strength of concrete, admixtures can help to extend the lifespan of concrete structures and reduce the need for repairs and maintenance.

The Importance of Proper Admixture Dosage

It is important to use admixtures in the correct dosage to achieve the desired results. Overdosing can lead to problems such as excessive bleeding, segregation, and reduced strength. Under-dosing can result in poor workability, longer setting times, and reduced strength.

The dosage of admixtures will depend on a number of factors, such as the type of admixture, the type of cement, and the environmental conditions. It is important to follow the manufacturer’s instructions and to test the mix to ensure that the desired properties are achieved.

Common Misconceptions about Admixtures in Concrete

There are several misconceptions about admixtures in concrete. One of the most common is that they are not necessary and can be replaced with additional cement or water. This is not true. Admixtures are specifically designed to modify the properties of concrete and cannot be replaced by cement or water. Further, users often think using admixtures can help them reduce cement usage, which is also false since the use of admixture only enhance the quality of concrete and help them in the long run.

Another misconception is that admixtures are expensive and can only be used in high-end projects. This is also not true. Admixtures are available at a range of price points and can be used in any project, regardless of its scale or budget. Further admixtures used in cement mixtures are only 2% of the cement quantity, hence hardly influencing the price of concrete development.

Conclusion: The Science behind Admixtures and Their Role in the Future of Concrete Technology

Admixtures are an important component of modern concrete technology. They provide a cost-effective way to improve the properties of concrete and extend the lifespan of concrete structures.

By using the right admixtures in the correct dosage, engineers can design concrete structures that are strong, durable, and resistant to the effects of weather and time. As the demand for sustainable and eco-friendly construction grows, admixtures will play an increasingly important role in the future of concrete technology.

Call to Action

For more information on admixtures and their benefits, contact Sturdflex today.