The Difference between Styrene-Butadiene – “Rubber and Latex”

Styrene Butadiene latex plays a significant role in waterproofing applications. Hence the demand for products developed using SB latex is always on the rise. To fulfil this rising demand and gain more profits many organizations often trick people by selling them SB rubber, instead of SB Latex. This is much more easily achieved since often the terms Styrene-Butadiene Rubber (SB Rubber) and Styrene-Butadiene Latex (SB Latex) are used interchangeably. However, they are two different materials that are used in different ways on a variety of products. Before we dive into the difference between the two materials, let’s take a look at the similarities, which create confusion for users, to consider one for the other.

How Styrene Butadiene Rubber and Latex are similar to each other

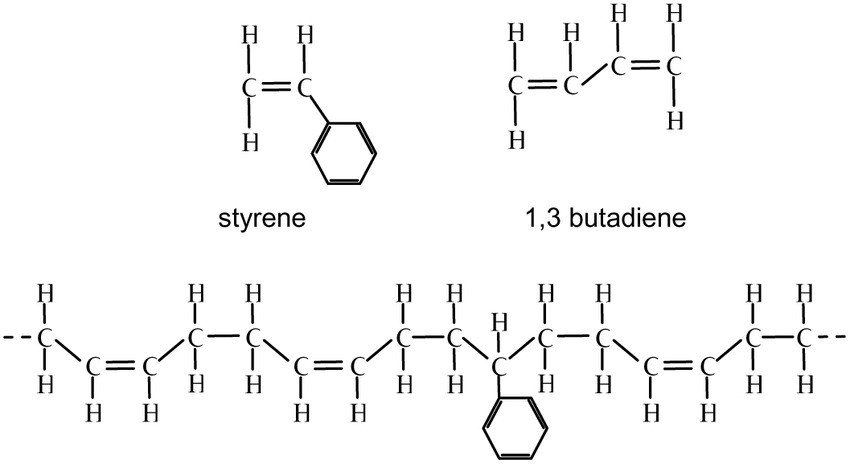

How SB Rubber and SB Latex are alike is that they are both synthetic polymers and they are usually created by a process called emulsion polymerization. They also share the same two components – an organic compound named styrene and an industrial gas called butadiene. Styrene is produced when benzene and ethylene react with each other at room temperature. It’s a colorless oily liquid and it has a sweet odor. While butadiene is a byproduct of the hydrocarbon ethylene and it is a colourless gas that smells faintly like gasoline.

Another way that SB Rubber and SB Latex are the same is that they both share several benefits over natural rubber. For example, they are usually less expensive, they are more resistant to abrasions and they age better because they harden over time, whereas natural rubber softens. Another important trait is that there are no allergens in SB Rubber and SB Latex, but there are allergens in natural rubber. In fact, allergies to natural rubber have become a rather big healthcare problem. The people who are most likely to develop these allergies are people who regularly come into contact with natural rubber, like healthcare professionals who wear rubber gloves and patients who require a lot of surgery.

Those are some of the main ways that SB Rubber and SB Latex are similar, but, what makes them different?

To understand that let’s dive into the detail of what each component is.

A walkthrough Styrene-Butadiene Rubber and its History

Styrene-Butadiene Rubber is most often made up of 25% styrene and 75% Butadiene, which is higher butadiene content than Styrene-Butadiene Latex and this makes it more elastic-like.

SB Rubber’s development traces back to the discovery of synthetic rubber in Germany in the early 1900s. At the time, the demand for rubber was high because of the burgeoning auto industry. To meet the need for rubber, in 1906, the pharmaceutical and chemical company Bayer gave their scientists a task. If they developed a synthetic rubber that would cost less than 10 marks per kilogram, they would be given a prize of 20,000 gold marks, which is just over $125,000 today.

Finishing the project just under the deadline in 1909 was Fritz Hofmann. However, his rubber still needed to be tweaked and in 1910, Bayer started selling the first synthetic rubber, which was a variation of Hofmann’s formula. Sales of synthetic rubber really took off with World War I because rubber became harder to get, but the need for rubber increased to help fuel the war machines of Germany and its allies.

In the years that followed World War I, chemists were still working on improving synthetic rubber. One such chemist was Dr Walter Bock, who worked at the German pharmaceutical company IG Farben, and he started experimenting with a process called emulsion polymerization. Bock found that when he used 25% styrene and 75% butadiene during the polymerization, the result was a tough and resilient synthetic rubber.

In 1929, a patent was filed for the first styrene-butadiene rubber, which was marketed under the name Buna S. The new copolymer was tougher and less rubbery than natural rubber, making it ideal for tires. That is still the most common use of SB Rubber; about half of all car tires use some form of SB Rubber.

However, SB Rubber is not just limited to tires. SB Rubber can be polymerized in different ways, which changes the consistency of the rubber. For example, when it is cold polymerized, the final product is used for filling in potholes and foam for mattresses.

A Walkthrough Styrene-Butadiene Latex and its History

Styrene-Butadiene Latex is the most common type of styrene-butadiene emulsion polymer and it’s also important to note that it’s not just different from Styrene-Butadiene Rubber; it’s also different from natural latex. Natural latex is a white sap that comes from Hevea Brasiliensis trees, which are more commonly called rubber trees. This sap can be refined and compounded, and this makes it readily processed and optimizes its physical properties. An example of a product that is made from natural rubber is white gloves that are used by medical professionals.

One of the main uses of SB Latex is that it is used for paper coating for products like magazines, flyers, catalogues and paperboard products like folding food cartons. SB Latex enhances the pigment’s binding power, it makes the paper smoother, stiffer, glossier, and brighter, and it is more water resistant. It’s also much less expensive than alternative coatings.

Another major use of SB Latex is back coating on textiles, including tufted carpets which are the most popular type of carpet in America; about 90 percent of carpets are tufted. The back coating holds the tufts in place, which improves stability and reduces fraying at the edge. However, the main reason SB Latex is the most used polymer for back coating is, because it has high pigment binding capability and strength.

Those are only a few of the uses for SB Latex and new ways of using it in different fields is being found all the time. Just a few more examples to show the diversity of the uses of SB Latex are that it can be used for running tracks, speciality coatings, adhesives, waterproofing and non-woven fabrics.

Difference between Styrene Butadiene Rubber and Latex

As for how SB Latex differs from SB Rubber, it has a greater crosslink density, and this gives it more toughness and strength compared to SB Rubber. This means that after it is stretched it will recover closer to its original shape.

Another notable difference between SB Rubber and SB Latex is that SB Latex products are much more diverse. SB Latex and the process conditions allow manufacturers to create dramatically different polymer compositions with different performance results. This allows products made from SB Latex; such as Latex Pro by Sturdflex Waterproofing Solution to meet a variety of requirements – in the waterproofing sector.